Development and characterization of flexible transducers based on piezoelectric nanowires

Published : 6 November 2018

MASTER Student Training : First Semester 2019

Development and characterization of flexible transducers based on piezoelectric nanowires

IMEP-LaHC / LMGP/ MINATEC / Grenoble-France

Keywords:

Nanotechnologies, Nanowires, Piezoelectricity, SALD

Training:

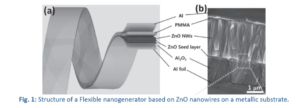

Very recently, the scientific community gets interested in nanowire devices, because of their unique electrical and mechanical properties due to their 1D structure. These properties could be exploited advantageously for several kinds of applications, such as sensors, actuators and energy harvesting devices (Fig.1)[1].

The training will mostly concentrate on the mechanical to electrical transduction using a composite material based on ZnO nanowires. These nanocomposites are expected to outperform thin piezoelectric films [2][3]. One of the technological challenges is the integration of these composites at low temperature over flexible substrates.

The objective of this training is to use the new technique SALD (Spatial Atomic Layer Deposition) [4] to deposit a seed layer of ZnO on different substrates (Elaboration at LMGP). This technique allows the depositions at very low temperature and very fast (up to 100 times faster than ALD) and work in air. The samples will be characterized using SEM, XRD and other conventional techniques. The NWs will be grown using the hydrothermal method and integrated into devices (Elaboration at IMEP-LaCH). The performance evaluation will be done at IMEP-LaHC or in the FMNT (Federation of Micro Nano Technologies) characterization platform (OPE)N(RA – http://fmnt.fr/plateforme-ope-n-ra/).

The training has three different and correlated goals:

- Participate to the fabrication of nanocomposite layers and triboelectric materials integrated on flexible substrates.

- Characterize electromechanically the fabricated devices thanks to a specific test bench.

- Eventually, the student could participate to the modeling of piezoelectric nanocomposites using the Finite Element Method (FEM) approach.

The achievement of these goals will allows us to better understand the underlaying physics and phenomena involved and to improve the performances of the composite material or triboelectric devices for energy harvesting or sensing applications.

The student will benefit from an established collaboration framework and will have the opportunity to contribute to national and European projects related to energy harvesting for autonomous systems.

References:

[1] S. Lee, R. Hinchet, Y. Lee, Y. Yang, Z.-H. Lin, G. Ardila, L. Montes, M. Mouis, Z. L. Wang, “Ultrathin Nanogenerators as Self-powered/Active Skin Sensors for Tracking Eye Ball Motion”, Adv. Funct. Mater., 24 (2014) p. 1163-1168.

[2] R. Tao, G. Ardila L. Montes and M. Mouis, “Modeling of semiconducting piezoelectric nanowires for energy harvesting and sensing” Nano energy, 14 (2015) p.62-76.

[3] R. Tao, M. Parmar, G. Ardila, P. Oliveira, D. Marques, L. Montès, M. Mouis, “Performance of ZnO based piezo-generators under controlled compression”, Semiconductor Science and Technology, 32(6) (2017) p. 064003.

[4] D. Munoz-Rojas & J. MacManus-Driscoll, “Spatial atmospheric atomic layer deposition: a new laboratory and industrial tool for low-cost photovoltaics”. Materials Horizons, 1(3) (2014) 314-320.

More info:

Duration: 4 to 6 months (first semester 2019)

Level: Master 2 (or Master 1) / Engineering School

Location: IMEP-LaHC / Minatec / Grenoble, France

Advisor: Gustavo Ardila (ardilarg@minatec.grenoble-inp.fr)

David MUNOZ-ROJAS (david.munoz-rojas@grenoble-inp.fr)

About the laboratory:

IMEP-LAHC / MINATEC / Grenoble

IMEP-LAHC is located in the Innovation Center Minatec in Grenoble. The main research areas concern Microelectronic devices (CMOS, SOI, …), Nanotechnologies, Photonic and RF devices. It works in close partnership with several industrial groups such as ST-Microelectronics, IBM, … and platforms such as LETI, LITEN, IMEC, Tyndall. The training will be within the group working on MicroNanoElectronic Devices / Nanostructures & Nanosystems. The trainee will have access to several technological (clean room) and characterization platforms.

LMGP / MINATEC / Grenoble

LMGP/ MINATEC / Grenoble

https://sites.google.com/site/workdmr/

Contacts:

Gustavo ARDILA :ardilarg@minatec.grenoble-inp.fr +33 (0)4.56.52.95.32

David MUNOZ-ROJAS : david.munoz-rojas@grenoble-inp.fr +33 (0)4.56.52.93.36

Contact us

Contact us How to find us

How to find us