All opportunities

Search...

Offers : 83

Edge-AI Solutions for Real-Time Hyperfrequency Material Characterization

Start date : 03/02/2025

offer n° CROMA-DHREAMS-01-08-2025

HyperAI : Solutions Edge-AI pour la Caractérisation en Temps Réel des Matériaux en Hyperfréquence

HyperAI : Solutions Edge-AI pour la Caractérisation en Temps Réel des Matériaux en Hyperfréquence

Context:

The electrical characterization of materials at hyperfrequencies is essential for understanding their intrinsic electronic structure and charge carrier dynamics. Permittivity and dielectric losses are a major concern in this field, as they directly impact signal integrity and propagation within high-speed electronic systems. Due to the stringent requirements of advanced System-on-Chip (SoC) and System-in-Package (SiP) technologies, in situ measurements are necessary, as manufacturing processes (ie solvent deposition, drying, and polishing) can significantly alter the electrical properties of materials, thereby affecting the overall performance of interconnects operating at frequencies up to 100 GHz. Conventional methods typically involve two stages: first, measuring the Sparameters of the structures using a Vector Network Analyzer (VNA), followed by solving the inverse problem through back-simulation (Houzet, 2021). The latter step is computationally intensive, often relying on simulation through finite element methods (such as Ansys HFSS) to address our specific challenges. Conducting such instrumentation remains a significant scientific challenge, particularly due to the high computational effort required and the lack of automation in such a method.

Integrating AI-driven instrumentation could streamline the process, reducing computational load and enhancing the efficiency of inverse problem-solving. A new hardware design is emerging from neural networks implementation with electronic circuits, often named edge AI. Artificial Neural Networks (ANNs) are computational models designed for real-time computing for applications such as classification of material samples through their data characteristics. Spiking Neural Networks (SNNs), also referred to as the third generation of ANNs, are emergent devices who effectively bridge the gap between ANNs and natural intelligence in low-power devices (Shrestha, 2022). This enables the implementation of AI solutions in-situ, ie as close as possible of the material under test. The implementation of SNNs is performed on neuromorphic processors such as Truenorth (DeBole, 2019), SpiNNaker (Furber, 2014), and Loihi (Orchard, 2021). These solutions fully exploit the sparsity of events and offer remarkable efficiency. However, neuromorphic chips cannot still be considered mainstream in the market, due to costs and availability. A low-cost, low-power solution is found on hardware-friendly neural networks in micro-controllers such as TinyOL (Ren, 2021), TinyTL (Cai, 2020), and MCUNet (Lin, 2020).

Objective:

The main goal of HyperAI is to accurately characterize the complex permittivity of materials using edge-AI solutions for real-time computing. This is approached through a two-stage methodology:

- a) Extraction method using transmission lines (e.g., CPW, CPWG, CPS) is employed on materials with known properties to build a database of measurement data. By varying transmission line types on the same material, we can create a robust dataset suitable for training a neural network, enabling automated and efficient material characterization.

- b) Transform an AI model into a hardware-friendly model. Flexibility, surface area, latency, memory consumption, energy efficiency, and reliability are addressed by this study. An STM32 (B-U585I-IOT02A) and an FPGA (ICE40UP5K-B-EVN) implementation should be investigated.

Keywords:

microwave instrumentation, convolutional neural networks, edge-AI, IoT.

Project Supervision:

CROMA laboratory is represented by Pietro M. FERREIRA, Full Professor at Université de Savoie Mont-Blanc, and Gregory HOUZET, Associate Professor at Université de Savoie Mont-Blanc. Prof. FERREIRA has a research interest in microwave instrumentation, neuromorphic circuits, and ultra-low power solutions. Prof. HOUZET has a research interest in materials science, microwaves, and applied physics. Candidate will be to the tools and scientific methods of the research topic. Practical activities and real-world scenarios are planned, including microwave measurements, scientific writing, communication and public speaking, result quality, time management, and research project management.

Candidate Profile:

The candidate profile required for the project is a young professional pursing a master’s degree in Eletrical or Electronics Engineering, interested in the scientific field of embedded electronics, microwave, and AI. He/She must be motivated, passionate about research in a multidisciplinary field and an organized person using scientific methods. He/She must justify good academic tracks in maths and applied physics; an experience in design flow; linguistic competence in English (B2 written and spoken); linguistic competence in French is a plus.

Intellectual Property:

Being fundamental scientific research, this subject is not attached to any industrial project. Intellectual property will be promoted through scientific communications favoring the open science policy of the French government.

Bibliography:

10.1016/j.mejo.2021.104990, 10.1109/MCAS.2022.3166331, 10.1109/MC.2019.2903009, 10.1109/JPROC.2014.2304638,

10.1109/SiPS52927.2021.00053, 10.1109/IJCNN52387.2021.9533927, https://dl.acm.org/doi/abs/10.5555/3495724.3496671,

https://dl.acm.org/doi/abs/10.5555/3495724.3496706.

CROMA Site Chambéry

Université Savoie Mont Blanc, Rue Lac de la Thuile Bat. 21

73370 Le Bourget du Lac Cedex

France

- Keywords : Engineering sciences, Electronics and microelectronics - Optoelectronics, CROMA, FMNT

- Laboratory : CROMA / FMNT

- CEA code : CROMA-DHREAMS-01-08-2025

- Contact : pietro.marisferreira@univ-smb.fr

(filled) Towards a universal optoelectrical microsensor: Microdevice for viscosity monitoring in liquid media

Start date : 03/03/2025

offer n° CROMA-PHOTO-10-28-2024

Towards a universal optoelectrical microsensor: Microdevice

Towards a universal optoelectrical microsensor: Microdevice

for viscosity monitoring in liquid media.

Key words:

Integrated photonics, sensors, device characterization.

Location:

CROMA Lab (UMR 5130).

Supervisors:

Elise Ghibaudo, Olivier Lavastre (CROMA) and Leticia Gimeno Monge (G2Elab).

Period and length:

Spring 2025, 6 months.

Contact:

Elise Ghibaudo, Olivier Lavastre (CROMA) and Leticia Gimeno Monge (G2Elab).

Additional information:

http://croma.grenoble-inp.fr/

Context:

Viscosity may be an indicator for either purity or pollutant presence in a liquid. For example, a reactive polymer can partially reticulate in presence of certain ions or molecules, thus changing the viscosity of the liquid media acting as a solvent. Common viscosity measurement solutions require sizable sample volumes (1 to 500 g) and durations (1 to 2h per analysis). Any solution that could speed up measurements and/or decrease the chemical sample volumes is extremely interesting.

CROMA expertise contributing to this project is twofold:

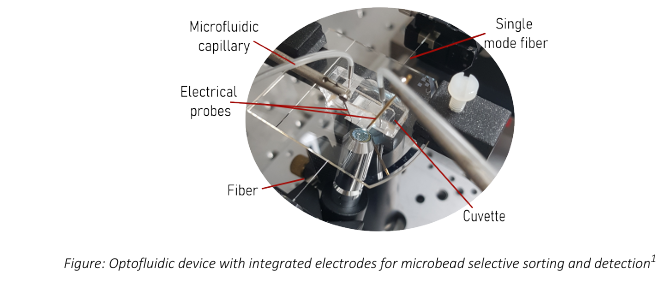

- Development of an integrated photonics device on glass1 (thus plastic free) for studying microbead behaviour (1 to 10 µm) in liquid media as well as associated quantifying and image processing techniques for microbead tracking.

- Development of a contactless analysis device2 (optical tweezer) GE2LAB brings to the project the expertise in microsensors including microfluidic and dielectrophoretic (DEP)3,4 function

Internship objectives:

In this project we aim at developing a brand-new generation of microdevices able to track viscosity evolution in real-time (Stop and Flow method) in a liquid environment. The working principle relies on correlating microbead movement, induced by DEP forces, to viscosity: the more viscous the fluid, the slower the microbead movement.

Internship topic :

Proof of concept validation opens the way for a universal optoelectrical sensor technology with numerous future applications, particularly in the field of sensors for healthcare, agri-food, security and environment industries. The change between application domains will come from the choice of an appropriate reactive polymer/targeted molecules or ions pair, likely to induce a measurable viscosity

variation.

Work and collaborative environment:

The recruited candidate will be trained in the different project aspects in order to complete the work:

- Bibliography on viscosity sensors and integrated photonics sensors physical principles

- Learning how to handle the sensor prototype for microbead selective sorting and detection, particularly for performing optical measurements

- Prototype adaptation for viscosity measurements: specs definition for measurable fluid types and viscosity ranges

- Setup of a Stop and Flow microfluidic measurement method adapted to the existing device

- Viscosity measurements with the existing device and the adapted protocol

Depending on the project progress and the candidate motivations, the orientation given to the internship final leg of the work may vary: valorisation of the obtained results, design of a new prototype optimizing one or more functions (microfluidic, electrical, optical).

The recruited candidate work will take place at CROMA and will have access to existing characterization and prototyping resources in the laboratory. The internship will be supervised by three researchers from CROMA and G2Elab who wish to join their expertise in multimodal sensing, microsystems and integrated photonics in the interest of developing this original viscosity.measurement method.

Profile requirements:

This internship subject is aimed at students at a Master 2 Research or last year engineering school level. The subject is adapted to training programs with a strong focus on micro nanotechnologies, photonics, biosensors, applied physics… The internship main content and objectives may be discussed and slightly adapted to match the candidate motivations as best as possible.

Applications :

To submit your application, please send an email (see contacts above) including a motivation letter, your CV, a copy of your grades and diplomas.

1 – M. Gardies, D. Bucci, & E. Ghibaudo, Sorting and sensing of dielectric microparticles by a multiphysics approach: integrated electro-opto-fluidic function for environmental application. In Integrated Optics: Devices, Materials, and Technologies XXVII, (2023). Vol. 12424, pp. 164-175. SPIE.

2 – C.-C. Chiang, M.-T. Wei, Y.-Q. Chen, P.-W. Yen, Y.-C. Huang, J.-Y. Chen, O. Lavastre, H. Guillaume, Optical tweezers based active microrheology of sodium polystyrene sulfonate NaPSS. Opt. Express 2011, 19(9):8847 8854.

3 – GIMENO L., TALBI A., VIARD R., MERLEN A., PERNOD P., PREOBRAZHENSKY V., “Synthetic jets based on micro magneto mechanical systems for aerodynamic flow control”, J. Micromech. Microeng., 20 075004, (2010), doi: 10.1088/0960-1317/20/7/075004

4 – GIMENO L., RAULY D., MARTINS J.M.F., NEHME H., XAVIER P., CHAMBEROD E., “AC dielectrophoresis of bacteria in coaxial mesoscopic structure potentially applicable for rapid detection and easy characterization at low cost”, BioEM 21, 26-30/9/2021 Ghent, Belgium, (2021)

- Keywords : Engineering sciences, Electronics and microelectronics - Optoelectronics, CROMA, FMNT

- Laboratory : CROMA / FMNT

- CEA code : CROMA-PHOTO-10-28-2024

- Contact : elise.ghibaudo@grenoble-inp.fr

- This Internship position has been filled. Thank you for your interest

Characterization of dielectric/silicon interfaces using second harmonic generation

Start date : 03/03/2025

offer n° CROMA-PHOTO-10-25-2024

Characterization of dielectric/silicon interfaces

using second harmonic generation

keywords :

caractérisation des interfaces diélectriques – semiconducteurs, optique non-linéaire.

Location:

laboratoire CROMA (UMR 5130).

Supervisors :

Lionel BASTARD (CROMA) and Irina IONICA (CROMA).

Period and duration :

Spring 2025, 6 months

Contact :

Lionel.Bastard@grenoble-inp.fr, Irina.Ionica@grenoble-inp.fr

More information :

http://croma.grenoble-inp.fr/en

Context & description :

A novel method to achieve non-destructive electrical characterization of interfaces using second harmonic generation (SHG) is currently under active development at the laboratory, within a collaboration with STMicroelectronics. This technique has passed the demonstration stage, but in order to be used as an in-line metrology tool in the industry, it needs to prove its ability to distinguish and quantify two different electrical properties of the interfaces: the trap density  and the fixed charges.

and the fixed charges.

In order to provide this functionality, a calibration procedure of the raw results from SHG measurement must be developed and it is the aim of the internship. The calibration procedure will be obtained by characterizing simple stacks using both SHG and other established characterization methods such as capacitance – voltage (C-V) measurements.

During the internship, the work will include:

- Understanding theoretical aspects: second harmonic generation, electric field distribution in semiconductor structures, charges and defaults at the interface between dielectric and semiconductor materials.

- Using SHG characterization tool available at CROMA to test simple stack structures under different configurations (influence of the laser power, influence of the substrate bias, …)

- Develop a model to fit the experimental curves.

- Compare the SHG measurement with C-V measurements in order to provide a method to separate traps and fixed charges densities from SHG measurements.

Desired profil:

The intern will work in close collaboration with permanent researchers and a postdoctorate fellow involved in this project from the laboratory. She/he will participate to the meetings with STMicroelectronics to discuss project advancements. We are looking for motivated candidates, with strong knowledge in non-linear optics and/or semiconductor physics and who are willing to actively participate to a collaborative project. During this multidisciplinary internship, the student will develop both experimental and theoretical skills that can be put to profit for his/her future career in both academic and industrial worlds.

Candidature : Pour postuler à cette offre, merci d’envoyer par mail (voir contact ci-dessus) votre candidature qui devra présenter une lettre de motivation, votre CV, une copie des notes et diplômes.

- Keywords : Engineering sciences, CROMA, FMNT

- Laboratory : CROMA / FMNT

- CEA code : CROMA-PHOTO-10-25-2024

- Contact : Lionel.Bastard@grenoble-inp.fr

(filled) New approach to develop selective surfaces for biosensors. Application to life sciences.

Start date : 04/03/2024

offer n° CROMA-DHREAMS-10-25-2024

New approach to develop selective surfaces for biosensors.

Application to life sciences.

Keywords:

Biosensor, Sensitive surface, Functionalization, Microelectronics, Optics, Nano, simulation and characterization of components.

Location:

CROMA laboratory (UMR 5130).

Supervisors:

Olivier Lavastre, Edwige Bano (CROMA) and Valérie Stambouli (LMGP).

Period and duration:

Spring 2025, 6 months (for M2) or 3 months (for M1).

Contact:

olivier.lavastre@univ-smb.fr, edwige.bano@phelma.grenoble-inp.fr or valerie.Stambouli-Sene@grenoble-inp.fr

More information:

http://croma.grenoble-inp.fr/en

Objectives of the work:

The CROMA and LMGP laboratories are working on new micro and nano electronic devices applied to life sciences. These are new generations of biosensors for the selective detection of target biomarkers. These are metabolites or proteins of strategic interest, for example, thrombin, dopamine, the various stress or happiness hormones, etc. The key point of selectivity is to develop reactive surfaces capable of modifying the electrical response of the devices, depending on

the presence or absence of the target biomarker to be detected. The classic surface modification strategy consists of functionalizing it through successive step-by-step chemical reactions on the surface of the device. However, this approach is very time-consuming and very often not 100% quantitative. Thus, the surface coverage is not homogeneous, which leads to poor selectivity and sensitivity. We wish to study a new approach without any surface chemistry. The concept is based on covering the surface with an organic film containing a specific probe (molecule, aptamer, etc.) to trap and quantify the target to be detected on the surface of the device.

Collaboration and working environment:

The experiments will focus on the use and characterization of organic film that can be a polymer, a viscous liquid, a wax (not soluble in water) with adequate

physicochemical properties for:

- Correct and permanent adhesion to the silicon carbide (SiC) surface

- Good dissolution and trapping of specific probe molecules

- No interference between the probe and the target

- An efficient electrical response of the surface during probe-target recognition.

Desired profile:

the 6-month internship is aimed at a candidate preferably in M2 (master Nanosciences – Nanotechnologies, filière Nanochimie), or PFE (filière Nanomed ou Matériaux, Phelma) internship.

Possibly, the internship can be adapted for a candidate in M1 (3-month internship).

Application:

please send your application by email (see contact above), which should include a cover

letter, your CV, a copy of your grades and diplomas.

References:

-Development of new High-throughput screening method to compare and to detect efficient catalysts for adhesive materials B. Colin,et al. Int. J. Adhesion and Adhesive. 2016, 68, pp.47-53.

-High-Throughput Screening of the Alkoxide/Oxime-Based Library An Alternative to Organotin Compounds for the Alkoxysilane Condensation in Adhesives and Sealants B. Colin, O. et al, ACS Combinatorial Science, 2019, ACS, 10.1021/acscombsci.8b00161.

-Progress in SiC nanowire Field-Effect-Transistors for integrated circuits and sensing applications, K. Zekentes, et al., Microelectronic Engineering 2022, Vol 255, 111704, https://doi.org/10.1016/j.mee.2021.111704

- Keywords : Engineering sciences, Electronics and microelectronics - Optoelectronics, CROMA, FMNT, LMGP

- Laboratory : CROMA / FMNT / LMGP

- CEA code : CROMA-DHREAMS-10-25-2024

- Contact : olivier.lavastre@univ-smb.fr

- This Internship position has been filled. Thank you for your interest

Study of selective contacts and p-type connection layers based on indium-free transparent conductive oxides for 2T tandem cells

Start date : 01/02/2024

offer n° CROMA-CMNE-10-15-2024

Study of selective contacts and p-type connection layers based on indium-free transparent conductive oxides for 2T tandem cells

For the development of new efficient p-type TCO thin films as key step toward transparent electronic, the internship focuses on the development of a p-type oxide thin film material for solar applications.

Context :

The evolution of photovoltaics (PV) technologies is critical in addressing global energy challenges by reducing production costs and improving solar cell efficiency. Tandem cells, which utilize multiple materials to capture a broader range of wavelengths from the solar spectrum, have emerged as a promising approach to boost efficiency. However, optimizing selective contacts, which facilitate electron transfer while blocking carrier recombination, is essential for their

implementation. Transparent conductive materials (TCMs) play a key role in this context, as they are vital for selective contacts and connection layers that ensure efficient charge collection and transport between different layers of the solar cell. While indium tin oxide (ITO) is widely used as a transparent conductive layer, its scarcity and high cost have spurred the search for alternatives with equal or superior performance. However, the best electrical properties are

found in n-type TCMs, while p-type TCMs exhibit lower conductivity and mobility, particularly on thermally sensitive and flexible substrates, which are increasingly important for next-generation PV technologies. This performance gap hinders the development of transparent, hole-conducting thin films and the realization of transparent p-n junctions, which could significantly enhance solar cell performance. To address this, a new class of materials with strongly

correlated electron phases has emerged as promising candidates for p-type transparent semiconductors. These materials have the potential to overcome the limitations of traditional p-type oxides, paving the way for efficient, flexible, and transparent solar cells that could revolutionize the future of PV technology.

Project description :

Within this context, the internship focuses on the study of the deposition of LaSrNbO3 (LSNO) thin films by metalorganic chemical vapor deposition (MOCVD). The optimization of the growth conditions will be performed by a detailed characterization study using a wide range of standard physicochemical analysis techniques (X-ray diffraction; scanning and transmission electron microscopy; energy and wavelength-dispersive X-ray microanalysis, Fourier-transform infrared and Raman spectroscopies). Transparent p-n junction devices will be subsequently fabricated by depositing the LSNO films on SrNbO3, one of the

best n-type TCOs. The electrical and transport properties will also be analyzed using numerous characterization (Van der pauw method, TLM, capacitance-voltage, KPFM, Hall effect).

Scientific environment:

The candidate will work in the LMGP, Materials and Physical Engineering Laboratory, in the FunSurf team inclosecollaboration with CROMA in the CMNE team, a specialist in characterization and electrical properties of semiconductors.

Located in the heart of an exceptional scientific environment, LMGP and CROMA offer the candidate a rewarding place to work. LMGP and CROMA website.

Profile & requested skills:

The candidate is an engineering school and / or Master 2 student whose training focuses primarily on materials science. Aptitude for teamwork, good spoken and written English will be appreciated. We are looking for a dynamic, motivated and autonomous student. Thesis continuation possible.

Internship allowance : Internship allowance will be provided.

Duration : 5 – 6 months.

Application Deadline : 30 November 2024

CONTACT :

Jean-Luc Deschanvres: jean-luc.deschanvres@grenoble-inp.fr; Tel: 04 56 52 93 34

Frederique Ducroquet: frederique.ducroquet@grenoble-inp.fr; Tel: 04 56 52 95 24

Johnny Azzi: johnny.azzi@grenoble-inp.fr

- Keywords : Engineering sciences, Electronics and microelectronics - Optoelectronics, CROMA, FMNT, LMGP

- Laboratory : CROMA / FMNT / LMGP

- CEA code : CROMA-CMNE-10-15-2024

- Contact : frederique.ducroquet@grenoble-inp.fr

Contact us

Contact us How to find us

How to find us

Telecharger ma sélection

Telecharger ma sélection Reset

Reset