Optimization of the recovery of critical materials in electronic devices by a microbial digestion process – influence of the design

Published : 30 September 2021

ENGINEER or MASTER 2 training period – 2022

Optimization of the recovery of critical materials in electronic devices by a microbial digestion process

influence of the design

Keywords:

Sustainable electronics, recycling; microbiology

Labs:

– Institut de Microélectronique, Electromagnétisme et Photonique ( IMEP-LAHC, GINP-CNRS-UGA-USMB)

Minatec – Grenoble, 3, parvis Louis Néel, BP 257, 38 016 GRENOBLE Cedex 1

– Institut des Géosciences de l’Environnement (IGE, CNRS-IRD-UGA-GINP)

70 rue de la Physique, Bâtiment OSUG B , BP 53, 38 041 GRENOBLE Cedex 09

– Laboratoire de Génie Electrique de Grenoble (G2Elab, UGA-CNRS-GINP)

Bâtiment GreEn-ER, 21 avenue des martyrs, CS 90624, 38031 Grenoble Cedex 1

Supervisors:

- XAVIER Pascal, pascal.xavier@univ-grenoble-alpes.fr, 04.56.52.95.69

- MARTINS Jean et SPADINI Lorenzo, jean.martins@univ-grenoble-alpes.fr, 04.76.63.56.04

- JEANNIN Pierre-Olivier, pierre-olivier.jeannin@univ-grenoble-alpes.fr, 04 76 82 64 46

Candidate profile:

Engineer or Master’s degree in process engineering, biomedical engineering or biophysics.

- Scientific background

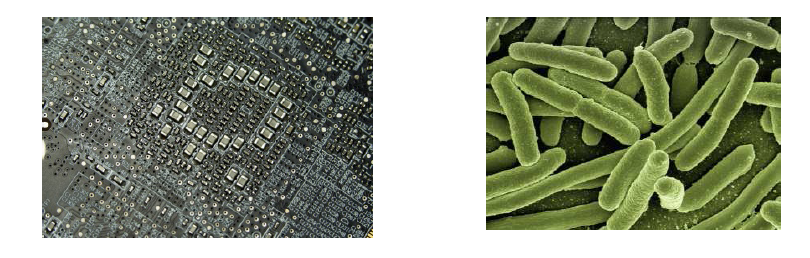

The ECB classified climate change as a systemic risk in 2021 and the recent IPCC report emphasised the indisputable role of human activities in global change. We need to reduce our consumption of fossil fuels by more than a factor of three if we want to reverse the radiative forcing, which will also reduce the consumption of all resources. Some of these resources, known as ‘critical materials’, such as certain metals and rare earths, are likely to be unavailable on the planet in the short term. The challenge for engineers is therefore to design systems that offer the same services but with at least a threefold reduction in environmental impact. At the same time, we should not seek to accumulate more services to avoid the rebound effect.According to a recent report by Global Waste Electrical and Electronic (WEEE) Watch, we generated 53.6 million tonnes of WEEE in 2019. Its volume is growing by 5% per year and the explosion of smart connected objects is not going to help reduce these numbers. So we literally have gold in our hands with WEEE ! It is important to ensure that

the critical materials they contain remain in the loop as long as possible. This circular economy would be economical

and, of course, environmentally friendly. - General objective of the course and research questions addressed

The aim of this project is to move towards an autonomous and environmentally friendly European industry by developing a completely new concept that correlates the design and recovery of critical materials at the end of the product’s life.

This prospective work is in fact part of the general issue of sustainable electronics put forward by Grenoble INP and by Europe. It is likely to be pursued as a thesis and will serve as a starting point for setting up projects at European level.

Financed by the Micro-Nano-Technology Federation (FMNT) of Grenoble, it aims to initiate interdisciplinary work between electronics specialists and microbiologists to determine the design choices for electronic circuits that will optimise the recycling rate of critical materials (metals, rare earths, etc.) in a recovery process by microbial digestion, while avoiding a deterioration in the performance of the said circuits. - Planned work

Tests under static conditions will be carried out in batch systems as well as in closed bioreactors which will be set up with a stirring and thermalization device. Several types of bacteria will also be used, such as model bacteria well known in the laboratory, such as E. coli and C. metallidurans CH34, but also anaerobic bacteria such as A. ferroxidans. The bacteria will first be cultivated under controlled conditions and then used at varying concentrations and under different conditions to be optimised to assess the extractability of the elements of interest contained in the electronic waste studied. The contents of metal ions recovered in the leachates from the batches and in the effluents from the bioreactors, as well as their chemical speciation, will be systematically quantified by ICP-OES or calculated by geochemical modelling to assess the efficiency of the bioleaching process.The electronic device chosen for the experimental tests will be a very simple circuit manufactured on the CEDMS platform of the UGA with different types of substrates (epoxy, ceramic), integrated circuit packages and components, with or without sparing varnish. The recovery of metals such as copper or gold will be tested with or without circuit crushing and with different crushing sizes.The “merit factor”, performance x recovery rate of critical materials, will be calculated for each case and a first Life Cycle Assessment (LCA) approach will also be made with a tool provided by ADEME, in order to provide reliable and robust comparison elements. IMEP-LaHC will bring its expertise in circuit design and testing, in particular RF. G2Elab will also bring its expertise in packaging and circuit failure analysis. IGE will contribute its knowledge and know-how in the control of microbiological and physico-chemical parameters of bacterial suspensions and bioreactors and the physico-chemical analysis of leachates. - References

– Desaunay A. and Martins J.M.F. Biosorption of Zinc by metabolically active and inactive cells of two contrasted Gram-negative bacteria: a subcellular distribution approach. Submitted to Intern. J. Environ. Res. Pub. Health.

SpecialIssue “Microbial Biotechnology Products for a Sustainable Bioeconomy”.

-Desaunay A. and J.M.F. Martins. A physical cell-fractionation approach to assess the surface adsorption and internalization of cadmium by Cupriavidus metallidurans CH34. J. Haz. Mat. 273: 231-238. 2014.

– Arda Isildar. Biological versus chemical leaching of electronic waste for copper and gold recovery. Environmental Engineering. Université Paris-Est; Università degli studi (Cassino, Italie), 2016. English.NNT: 2016PESC1125. tel-01738056- Jadhav, U. and Hocheng, H. Hydrometallurgical Recovery of Metals from Large Printed Circuit Board

Pieces. Sci. Rep.5, 14574; doi: 10.1038/srep14574 (2015).

– https://hal.univ-lorraine.fr/hal-02431903/document

– https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3715747/

– Abhilash et al. Microbial Processing of Waste Shredded PCBs for Copper Extraction Cum Separation—Comparing

the Efficacy of Bacterial and Fungal Leaching Kinetics and Yields. Metals 2021, 11, 317.

https://doi.org/10.3390/Met11020317

Contact us

Contact us How to find us

How to find us