Temperature Dependence of Ion-Exchanged Waveguides on Glass: From Fabrication to Environmental Impact

Published : 27 October 2025

M2 Internship Proposal

Temperature Dependence of Ion-Exchanged Waveguides on Glass:

From Fabrication to Environmental Impact

Location: CROMA Lab (UMR 5130), Grenoble, France

Supervisors: Lionel BASTARD and Davide BUCCI

Period and length: Spring 2026, 6 months.

Why this project?

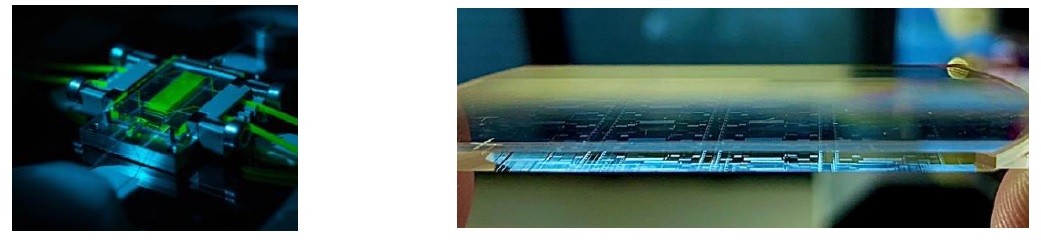

Waveguides are at the heart of many optical technologies — from telecommunications to lab-on-chip sensors. Among the different platforms used to build these devices, glass stands out as a low-cost, robust, and optically transparent material [1][2]. It’s also compatible with microfluidics, making it ideal for next-gen bio-sensors.

At CROMA, we’ve been developing integrated optics on glass for nearly 40 years using a technique called ion exchange. This process changes the glass’ refractive index by replacing sodium ions (Na⁺) with other ions like potassium (K⁺) or silver (Ag⁺), allowing us to “write” waveguides into the material.

But there’s a challenge: temperature. Ion exchange relies on heat to diffuse ions into the glass (typically above 300°C), and later steps like wafer bonding[3] (100–150°C) could potentially affect the waveguides’ quality. So how stable are these waveguides across different temperatures? And at the same time, can we make this process more eco-friendly?

Internship Objectives

During this internship, you’ll help answer that question by working at the intersection of materials science, integrated optics, and sustainability.

You will:

- Do a literature review on ion exchange in glass and temperature effects.

- Use CROMA’s cleanroom facilities and ion-exchange tools to produce test samples under varying thermal conditions.

- Measure how light propagates through the waveguides.

- Perform a Life Cycle Analysis (LCA) of the ion-exchange technique and compare it to other fabrication methods (e.g. silicon photonics), contributing to the push for greener photonic technologies.

What you’ll use and learn :

- Ion-exchange waveguide fabrication

- Optical characterization techniques

- Cleanroom fabrication tools

- Simulation tools for optical design

- Life Cycle Assessment (LCA) methodology

Ideal Candidate :

- M2 student in photonics, applied physics, materials science, or nanotechnology

- Interest in integrated optics, fabrication technologies, and sustainable engineering

- Motivation to work in both experimental and analytical environments

________________________________________________________________________________

# integrated photonics

# glass technology

# life-cycle analysis

Desired profile & skills

2nd year Research Master or

3rd year Eng. School

– Microtechnology & fabrication

– Photonics

– Affinity & curiosity for experi-mental and numerical work

Send application to:

Lionel BASTARD

Davide BUCCI

Technical references :

[1] microsensing of plutonium

[2] glass integrated laser

[3] wafer bonding

Contact us

Contact us How to find us

How to find us